About Systema GmbH

Integration of manufacturing systems, extensions, consulting and customized software solutions for vertical industries of discrete manufacturing are the core competence of Systema GmbH. Systema has over 200 employees at 8 locations worldwide. The good reputation of our brand is based on more than a quarter century of business based on an ethic of mutual respect and trust - among our team, our customers, partners and competitors.

Initial situation

We develop extensions for the SAP Manufacturing System for our customer, a well-known company in the precision mechanics and optics industry.

These plugins complement the existing functionality and provide users with individually customized interfaces depending on their specific requirements.

To ensure the quality and stability of our development, we were looking for a way to test these plugins directly in the SAP Manufacturing System.

Since we had already worked successfully with QF-Test in other projects, it was our first choice of testing tool.

Objective

Our goal was to recreate the actions of an actual user in the tests in order to reproduce the processes in production as close as possible.

The execution of the tests must be automated to reduce manual efforts.

Implementation

One requirement for the tests is that they replicate reality as closely as possible.

GUI test tools such as QF-Test, which actually interact with the user interface, represent the best solution here.

In preparation, test cases were created based on the specified requirements, which were then grouped into scenarios. The result was a detailed test plan, which was implemented by the automation team using QF-Test.

Technical realization

The test creation with QF-Test was mostly done using the recording function.

Problems arose due to the use of generated component IDs, which prevented unambiguous identification and thus made the tests non-reproducible.

To solve this problem, generic components were created, which enabled reproducible resolution of the target components using regular expressions and an appropriately configured CustomWebResolver. The excellent support of QFS, who helped to develop this solution, should also be mentioned here.

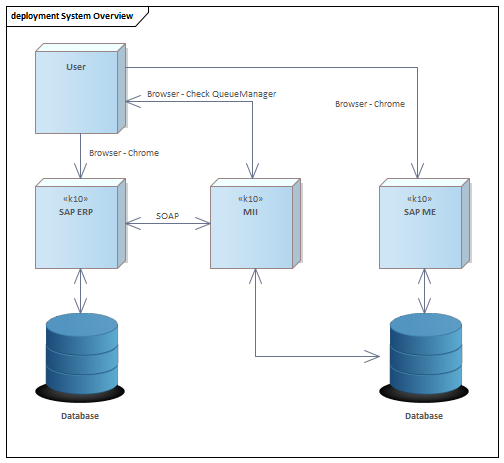

During test development, another challenge became apparent. The SAP Manufacturing System consists of several components, which together provide complex data. Our target system is the ME as the front-end with the MII as an extension of the back-end. In addition, there is the ERP system.

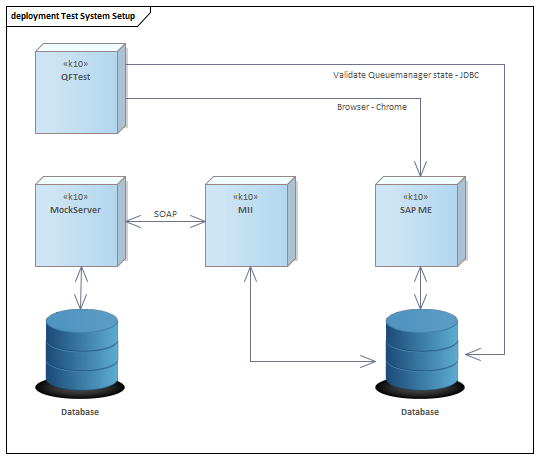

To reduce complexity and get reproducible results, we decided to simulate the ERP (mockup).

Using the MockServer framework, we developed this mock, which provides predictable data.

MockServer is a separate software project and contains different templates, which are preconfigured for different functionalities. In order to implement new requirements, we just had to create a suitable template.

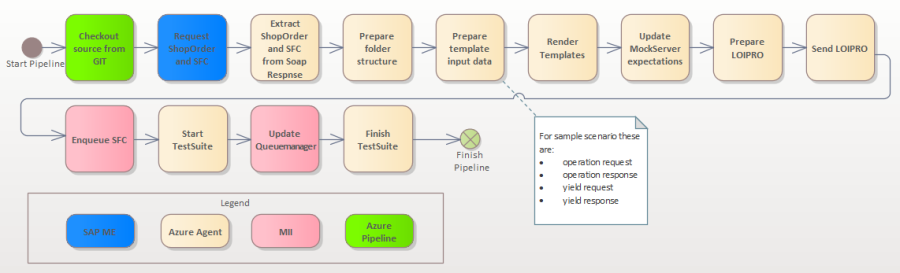

After completing the test development and the successful manual testing, the next step was to automate it. A Microsoft Azure pipeline was used for this.

The pipeline allows us to automatically prepare the test data, pass user data and variables to the test suite, evaluate the results, and then clean up all systems.

Since both MockServer and the QF-Test test suite are maintained in GIT, we can ensure that the latest version is always used at runtime.

Conclusion and outlook

By using MockServer and QF-Test, a combination of backend (logics) testing and GUI testing was achieved. This allowed us to efficiently build a realistic and reliable test environment to automate testing plugins developed for our customer directly in the SAP Manufacturing system. The principle of continuous testing was implemented by integration into an Azure pipeline. This achieves fast test feedback and thus effectively prevents early regression, as well as minimizing the manual testing effort.

In the further course of the project, the tests will be continuously maintained, improved and expanded in order to ensure that new functionality is also secured.